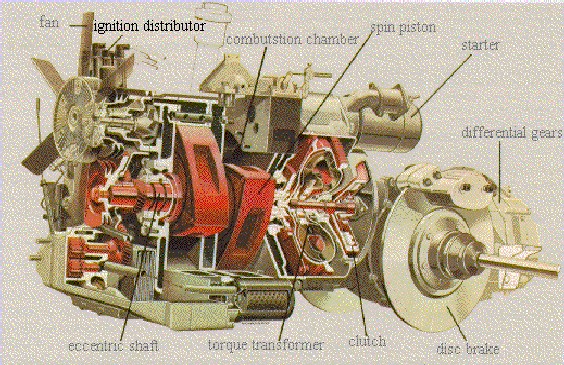

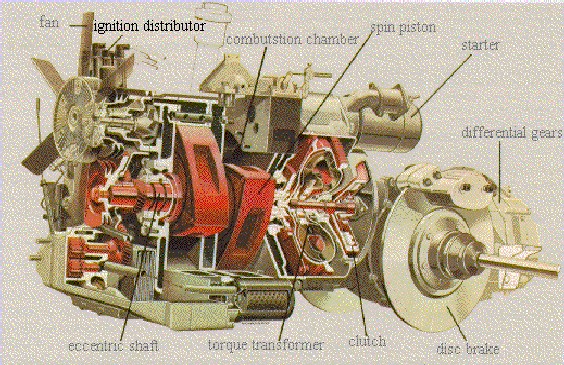

ROTARY ENGINE

The Wankel engine is a rotary motor. At one time Peugeot

used it in a production car and MAZDA still uses the Wankel in some of

its models Here are various advantages:

- For gas control no valves and connecting rods are needed.

- Its weight is very low in comparison to a piston engine.

- Its volume is about half that of the piston engine with

the same power.

- The production costs are lower compared to other motor

types.

- It can reach higher revolutions per minute.

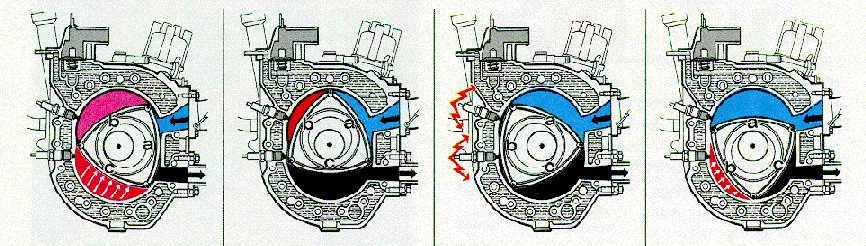

DESCRIPTION OF THE 4 CYCLES OF THE WANKEL ENGINE

- After all consumption gases have been pressed out (see

colour black and a) the intake cycle begins. Petrol air mixture

flowes through the inlet channel into the blue chamber.The piston rotates

to the left and compresses the fresh gas.

Chamber a sucks in fresh gas, while chamber b starts to compress

the gas. In chamber c the gas is completely burned and can flow

out (see black colour).

- Chamber a sucks in petrol air mixture. Chamber

b has compressed the gas completely. Now two ignition sparks ignite

the compressed gas simultaneously. Chamber c presses out the burned

gases.

- Chamber a is full of fresh gas. The compression

cycle begins as soon as chamber a is closed. In chamber c

the burned gases decompress and press the piston into spin direction. Meanwhile

chamber c presses out burned gases.

Sources: "DAS WILL ICH VON DER TECHNIK WISSEN",

AUTHOR: AXEL REX and BOMIN SOLAR, SIGNON SAN DIEGO,

FUTURE DRIVE, WORLD WATCH.

Back to CONVENTIONAL COMBUSTION ENGINES

or CAR OF THE FUTURE